You’ve bought your reverse osmosis system and used it without any problems. You feel healthy and happy until the day the system stops doing what it’s designed to do: produce RO water.

Below are some of the most common questions and RO problems I get asked about. I’ll provide you with some DIY instructions so you can get it fixed on your own without having to call someone to do it for you. Plus, the costs for replacing RO systems can add up, so it’s always best to try to fix your RO problems on your own first.

Table of Contents

Common Reverse Osmosis Problems and Fixes

Your reverse osmosis system should last up to 15 years, but you may have problems during that time.

You may experience low to no water pressure and, thus, low water flow. The water tank may not fill up, constantly draining, or the drain line keeps running.

It may be a simple issue like a faulty reverse osmosis automatic shut-off valve (ASO), or the pressure bladder in the tank has developed a leak.

Let’s discuss a few ways to troubleshoot your system.

Reverse Osmosis System Leaking

Discovering a leak in your RO system is not uncommon.

When your tank leaks, the first thing to do is switch off the cold water line that feeds into your RO system.

There are several reasons this can happen. If you are familiar with DIY, you should be able to fix these problems yourself.

Leak at the Faucet

This may be caused by a loose connection in your RO system, or more commonly, it may be caused by an air gap leak.

You may need to tighten all the connections if it’s the former. Ensure all the tubing is inserted correctly into its respective valves, ports, and the drain saddle.

Ensure the holes between the drain saddle and the drain hole are aligned — if they aren’t, this could restrict the water flow.

If the leak is from the bottom of the faucet, you will need to replace it.

Leaking from the Air Gap

If the reverse osmosis drain line keeps running, the problem may also be caused by leakage from an air gap.

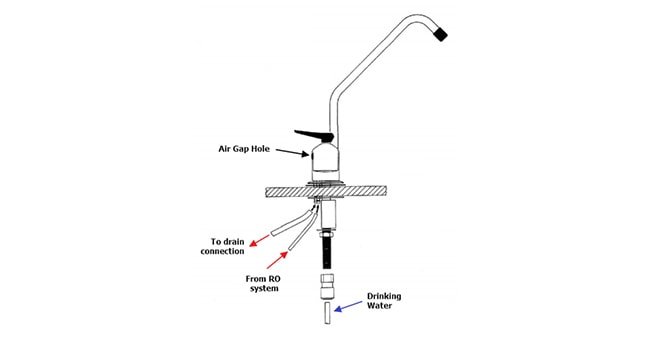

An air gap is a space between a water outlet e.g, a faucet, and the flood level of a container, e.g., a sink or tank, or with an RO system, the drain.

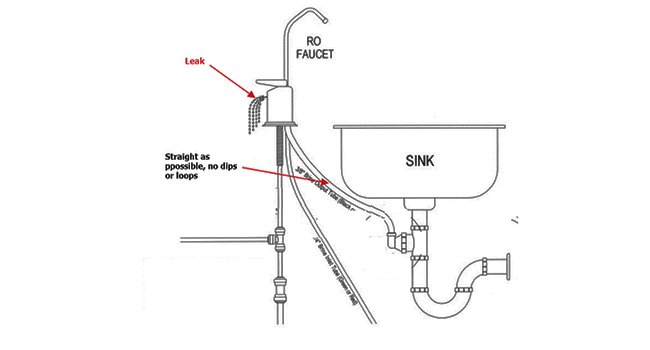

Gravity directs the flow of water between the air gap and the tank — in an RO system if the tubing between the faucet and the drain saddle is too long, i.e., it does not lie as straight as possible to the connection, water will leak out of the air gap at the bottom of the faucet.

An air gap leak may also be caused if debris has accumulated in the drain line, causing it to clog. Try to avoid putting food and other solids down the drain.

The drain line can be cleaned with a wire brush or pipe cleaner and environmentally-friendly cleaning fluids.

Ensure the drain saddle and line are kept clean to prevent mold growth.

Reverse Osmosis System Draining Continuously

There are several reasons why your reverse osmosis constantly drains.

Although wastewater is generated during the RO process, a non-stop flow of water means something is wrong with the system.

Problems may include:

ASO valve

The ASO valve is controlled by pressure from the tank. A full tank exerts 35-40 lbs of pressure on the valve, at which point the water flow cuts off. A faulty valve will result in the water continually flowing into the drain.

A damaged ASO valve would need to be replaced.

Check Valve

A check valve is a one which allows the water to flow in one direction: if the water flows in the opposite direction, the valve will close to prevent leakage and backflow.

A damaged check valve will allow unrestricted water flow in both directions as the RO system cannot attain the required pressure to shut down.

A faulty check valve would need to be replaced.

RO Membrane

The life of an RO membrane depends on several factors, from how hard or soft (alkaline or acidic) the water is.

RO membranes also cannot withstand temperatures higher than 113o F.

Generally, however, you can expect an RO membrane to last about five years. They should be inspected regularly for mold growth or damage, in which case they should be changed immediately.

A Flow Restrictor

A flow restrictor limits the flow of RO wastewater. It maintains the high pressure of the RO membrane. If this does not work correctly, high-pressure water from the pump will flow unimpeded from the RO membrane reject water outlet.

This will cause low pressure in the RO membrane and therefore a high volume of wastewater.

The rating of the flow restrictor should be 4x the capacity of the RO membrane or at least 18 fl oz per minute.

A flow restrictor of the wrong size will either cause the RO membrane to become blocked or the water pressure to be too low for effective filtration.

The flow restrictor should be changed when the RO membrane is changed.

Reverse Osmosis Water Flow is Slow

You pour yourself a glass of water from your RO system, and all you get is a trickle. Of course, your tank may be empty, but there are a few other reasons why your reverse osmosis water flow is slow.

Low Tank Pressure

To test how full the tank is, pick it up! At full capacity, it will weigh about 20 lbs, so you will easily be able to judge how much water is in it.

If the tank is full, but you are still unable to run water, you will need to test the tank’s air pressure when it is empty. You can use a bicycle or tire pump to test the pressure: this should measure between 6-8 psi when empty and between 35-40 psi when full.

Ruptured RO Tank Bladder

Most often, the cause of slow water flow is the condition of the air bladder contained in the tank.

If this is ruptured, it will leak air and cannot build up enough pressure to pump water out of the tank.

If the bladder pressure is low, you can try to repressurize it by slowly pumping air in, and measuring the psi after each inflation. However, if this does not work, you will have to replace the entire tank.

Clogged RO Membrane

Another cause may be that a clogged RO membrane is causing slow water flow.

The RO membranes will clog up if they have to process hard water. If the water contains high concentrations of calcium, magnesium, iron, and sediments, the lifespan of the RO membrane will be shortened.

Pre-filter carbon cartridges should be replaced every 3-6 months, as this can also affect how long a RO membrane remains effective.

Kinked Water Line

The third reason for slow water flow is that the tubing may be kinked. Depending on the severity of the distortion, you can either try to straighten it or it may have to be replaced.

Crimped tubing will reduce the water pressure and, thus the flow.

Reverse Osmosis Tank Not Filling Up

Your reverse osmosis storage tank not filling up could be caused by several factors.

You may simply be using the water too fast, and the tank is not able to fill up, but there could be other underlying reasons.

Water Pressure

The requisite reverse osmosis water pressure for the membrane to work effectively is 40 psi. Anything less than that and the amount of water filtered will be reduced.

In this case, you can buy a booster pump to increase the pressure sufficiently or simply use a bicycle pump.

On the other hand, if the water pressure is too high, the water will not be able to reach the tank.

To fix this issue, you can buy a pressure-reducing valve (PRV)

The optimum pressure is between 60-80 psi.

Clogged Filters

Your RO system pre-and post-filters may be clogged. If this happens, there will be reduced water flow to the semipermeable membrane, further resulting in the tank not being sufficiently filled.

The stages of RO filtration could include sediment and GAC (granular activated carbon) filters, then the semipermeable membrane, and finally a carbon polishing filter. Some RO systems offer a further filter to replace some of the minerals removed during the RO process.

Clogged RO Membrane

RO membranes may clog up if the water is too alkaline, i.e., hard.

To alleviate this, you can either use a water softener or replace the membranes more frequently, which will add to your costs.

Clogged filters will have to be replaced as they will not filter the water to an acceptable standard, thus preventing the whole RO process.

Taste and Odor in RO Water

The point of producing reverse osmosis water is to have access to pure, filtered water free of unhealthy minerals and chemicals.

Any RO water that has an unappetizing odor should be discarded, and the RO filters replaced immediately.

It is possible to buy an RO system with a modular filter configuration. This means that all the filters and membranes are disposed of and replaced simultaneously, lessening the risk of contamination.

Water Smells Fishy

RO water with a metal taste is usually caused by metal elements like barium and cadmium.

Another cause could be the presence of chloramine, a compound of chlorine and ammonia. This is used to disinfect public water sources but may leave you with a fishy odor in your RO water.

Water that is warm and indirect sunlight makes perfect conditions for algae blooms, which usually occur in the summer. This is especially prevalent in lakes and water reservoirs.

Water Tastes like Plastic

If your RO water tastes like plastic, it indicates your system is not working properly.

Also see: Water Brands that use Reverse Osmosis

The filters and membranes must be replaced regularly, and the entire system should be cleaned and sterilized regularly.

Water Tastes Funny

Contaminants can accumulate in your RO system, and if this is not cleaned regularly, harmful biofilm can build up, potentially causing serious health problems. Any RO water that has an odd taste should be discarded and the filters replaced before any more water is processed.

How to Improve the Taste of RO water

Adding a carbon filter to the RO process will assist in removing contaminants like hydrogen sulfide, which makes water smell like rotten eggs.

It is also an option to remineralize RO water, which will replace some of the minerals of the beneficial salt that are removed during the RO process. These include sodium, magnesium, and calcium. These will make RO-treated water taste more like ‘normal’ water.

Reverse Osmosis System Making a Noise

If you hear strange noises from your RO system, it is generally nothing to be concerned about.

Sounds from your RO system will be caused by the tubing being under pressure — that is how the system works.

Hissing sound

Any hissing sound that emanates from the RO system is likely to be caused by air pressure in the air gap or the drain. This usually happens after the filters are replaced and should not last longer than a day or two.

Check that the tubing and drain lines are not blocked and that the water has a clear flow.

Clicking noise

Any clicking noise can be eliminated by shortening the tubing. This will reduce air bubbles and subsequently reduce the noise.

The vibration of the tube, which is under pressure, may make a noise.

Reverse Osmosis System Gurgling

If your RO system gurgles, it is probably caused by a difference in level between the drain line and its connection to the drainpipe. Water leakage from the end of the pipe can cause the drain tube to siphon and make a gurgling noise.

The secret is to have no low points in the drainage tubing — if it flows vertically the water will drain steadily with no sound effects.

When the pressure tank is being filled, there may be some gurgling, but there should be no noise once this has been achieved.

Maintenance Checklist

An RO system can be expensive and should be checked regularly for defects and impurities.

RO System Maintenance Checklist

1. Testing the RO feed water

2. Testing the chlorine and alkalinity levels

3. Setting timers for pre-filters and water softeners

4. Noting the RO pump pressure, flow rate, and water temperature

5. Logging water flow rates

6. Testing RO wastewater and flow rates

7. Checking pressure gauge readings

8. Changing pre-filters

9. Changing the semipermeable membrane

Some of these checks may need to be undertaken by a professional company.

Full Checklist PDF here.

Conclusion

If you maintain your RO system and repair any minor leaks and damage as they occur, it should last you up to 15 years.

Follow these troubleshooting guidelines and get years of pure water from your reverse osmosis system.

Also, see my guide on the best under sink filters if you are looking to get a new model.

What about the Waste Water Flow Restrictor? I just replaced my 75 GPD membrane and would sure like to know the optimum restrictor size for the most economic use of municipal water while not reducing the quality of RO water!