A well is a lifeline to homes that can’t connect to a municipal water supply. When that well fails to produce water, it can be an expensive, damaging prospect for those that depend on it.

The important thing to consider is to not panic. There are often simple solutions to getting the water flowing again that you can do yourself, or that are relatively inexpensive if you have to call in a professional.

What can stop the water from flowing?

- Pressure tank

- Low water level in well

- Capacitor failure in well control box

- Pump failure

- Broken/shorted wires to well pump

- Broken water line

We’ll take a look at the steps you can follow to solve the problem. If it’s a simple repair we’ll walk you through it. If it requires a professional, we’ll tell you when to make the phone call.

Your Pump Seems to Work, but there is no Water. How to Repair it?

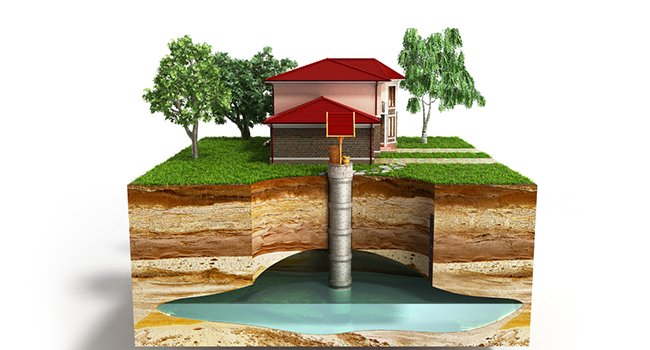

Knowing how a well is laid out will help you determine what to do next.

A private water well has five main components:

- Well

- Power supply

- Pressure tank

- Pump

- Waterline

Well

Modern well pumps come in various styles, but they all do the same job. A well pump drops vertically down the casing of a water well to a level below the static level of the water in the well.

A good rule to follow in a healthy water well is to have the pump just a few feet above the bottom of the well so it can draw from the standing water column above it. Water flows into a well casing from perforations in the walls of the casing.

Water doesn’t exist in pools underground but is contained in levels of water-bearing sand, or gravel.

Power Supply

Well pumps are powered by either 120v or 240v in American models. The 240v pump is better suited for deeper wells that draw a lot of water.

The smaller 120v pumps are generally used in shallow wells less than 80 feet deep.

You can tell the difference easily by the number of wires supplying the pump with electricity. 120v systems usually have two wires, one black, one white, and a ground wire that is usually green. 240v systems have three wires, black, white, and red, along with the same green grounding wire.

The power supply for the pump is located away from the pump, usually in a basement, crawl space, or in a standalone structure near the well.

The power supply is powered with a direct line to the electric panel in the home.

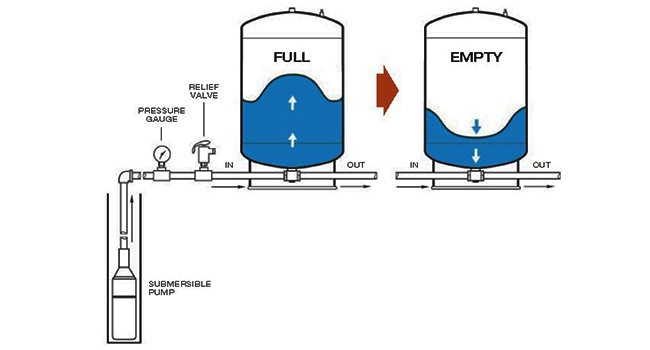

Pressure Tank

A pressure tank is a device that greatly extends the life of a well pump. A pressure tank is a steel container with an air-filled rubber bladder inside. The rubber bladder maintains pressure to the various sinks, toilets, showers, and spigots inside and outside your home.

The pump power is connected to a pressure switch on the pressure tank. This pressure switch has a setting for the lower and upper limits of pressure in the tank. Most homeowners set the lower limit at 40 psi and the upper at 60 psi.

When the water drains out of the pressure tank as you use it, the pressure drops. When it hits 40 psi the switch powers the pump and it fills the tank again, shutting off when it hits 60 psi.

Pump

As described above, there are two power models for home well systems. The pump is a long, narrow cylinder that can easily slide in and out of the well casing. Most pumps are only four inches or smaller in diameter but can be as long as 30 inches.

The pump does the physical work of a home well system. It pumps water vertically from deep in the well, supplying the pressure tank with water.

In a healthy system, the pump only runs for a short time as it fills the pressure tank. A pump that runs constantly will greatly shorten the lifespan of the motor in the pump.

Waterline

There are two water lines in a home well. The first is the vertical water line connecting the pump to a device called a “pitless adapter” or to a right-angled piece of plumbing pipe in a well pit.

Next Article: Our Recommended Best Water Softener For Well Water

The vertical line is heavy-pressure PVC in modern systems, but if you have an older well, it could be made of sections of galvanized steel pipe.

The pump pushes water up through the vertical water line where it makes a right angle into your home.

A pitless adapter is a V-shaped interface that allows a pump to be connected or disconnected by sliding it in or out of the adapter. This greatly reduces the effort and cost of making pump repairs.

Older systems will have a 90-degree angle coupling that connects the water line to the pump to the water line going into the home.

The water line from the well pit or pitless adapter must be buried below the frost line if you live in a cold climate. If the line isn’t buried deep enough, the pipes may freeze and burst in cold winter weather.

Reasons There Would Be No Water From Your Pump

Now that you know how the system is designed, it will be easier to troubleshoot the problem.

Most Common Issues in order of Frequency

- Pressure tank

- Water level in well

- Pump

- Waterline breakage

- Power supply compromised

Pressure Tank Issues

The most common issue with a well is the pressure tank. It can fill with sediment, reducing effectiveness, the bladder can rupture, making the pump run constantly against a full tank or water, or it can rust, rupture and spill water everywhere.

Recommended Reading: Best sediment filter for well water

Is your well pump slow to build pressure? If so, the first place to look is the pressure tank.

Is the well pressure switch clicking on and off? That’s also an indication of pressure tank issues.

If you are in drought conditions or have suddenly made greater demands on your well, the static column of water may have dropped.

Wells do run dry after a while. If your well has been drawn down heavily, it may not have the ability to produce water from the surrounding sand and gravel as quickly as it once did.

Pump Issues

Pumps fail eventually. If you have dissolved solids, hard water, or a lot of sand in your water, it can reduce the life of the pump.

The pump can still be running but producing little water if the impellers inside the pump have worn down. They’ll spin constantly, but can’t grab the water and send it up the well.

If the well pump runs but no water pressure is present, you may have bad impellers.

Water Line Breakage

A broken water line connecting the pump inside the well casing is very rare, but the supply line from the pit to the home can be broken by freezing and bursting, by an earthquake, or by someone digging and cutting the line.

Power Line Breakage

Power lines can become corroded, broken, or sliced in half by someone digging in the area. The most common problems come when the line moves in another direction.

Above the pump, you’ll see a cap with wires descending inside it to the pump. This is the most common area for power problems to occur.

Signs of Well Pump Failure

- No water

- Lower water pressure

- Pump runs constantly

- Pressure switch trips on and off constantly

- Water spraying around the pressure tank

- No water to the home but a wet spot in the yard

Troubleshooting Common Well Pump Problems

Waterlogged Pressure Tank

By waterlogged we mean a full tank that isn’t switching on or off. This is usually a pressure switch problem.

If the switch is clicking on and off repeatedly, you have an issue with the pressure tank. The bladder may be compromised, it may be filled with sediment or the pressure in the bladder may have released too much air, requiring you to fill the bladder again to standard with an air compressor.

To check this you need to measure the air pressure with a tire gauge. There is an air test valve on the top of the tank. Use your tire gauge there.

If the pressure is good you need to examine the switch closely. Remove the cap, shine a light on the wiring and check for corrosion or signs of a burned wire. If they appear, you’ll need to reconnect the wires, install a new pressure switch or call a professional.

- ADJUSTABLE PRESSURE FUNCTION: This is a water pump pressure control switch for perfect pressure control. Pressure switch with 40-60 psi pressure setting range activates an electrically driven water pump within a power circuit when the adjustable rising and falling thresholds are reached.

- WIDE APPLICATION: 1/4″ Female NPT, standard water well pump replacement switch designed for use of electrically driven water well pumps of all types (Jets, Submersible, Reciprocating etc).

Pressure Switch Problems

The pressure switch sits at the base of the pressure tank. It rests above the water line entering the home and the water line exiting the tank to the home. The pressure switch is attached to the tank via a “T-fitting” One side of the T receives the water, the other side allows the water out of the tank.

The pressure switch controls the water entering the tank by shutting off the pump when it hit the upper PSI limit. It turns the pump back on, allowing more water to flow into the tank when the lower PSI limit is reached.

Isolated pressure switch problems are rare, they are almost always in connection with a pressure tank issue, but they do happen.

If the switch won’t turn on, try manually engaging the switch by pushing on it with a screwdriver. If it still won’t fire the pump, you probably have an issue with the pump control box.

If it won’t switch off you have a problem with the pressure tank.

A well pressure switch clicking on and off is also a pressure tank issue.

Leaky lines

A leak can create a lot of problems, making the pressure tank switch on constantly, running the pump too much, and adding to your electricity bill. A leak is easy to spot inside the home, at the pressure pump, or inside a well pit.

If the leak is underground you can check it by filling the pressure tank until the switch clicks off then shutting the outgoing valve from the pressure tank to your home.

In a healthy system, there is no place for the water to go so the tank will sit idly for days or weeks until demand returns. But, if there is a leak underground, the switch will kick back on after a while indicating there is water flowing out of the line in an underground leak.

Well Pump Will Not Shut off

Well pump troubleshooting is one of the most important steps you must take to isolate the problem and reduce the overall cost of a repair.

If your pump runs constantly, and will not shut off, it’s most likely a pressure switch issue. The switch may be fused from a short, not allowing the spring to release when the pressure reaches the upper limit.

Alternatively, is the well pump slow to build pressure? That can be an indication of impeller failure. That can make a pump run constantly.

This will quickly destroy a pump.

If the well pump runs but no water pressure flows, you have a pump problem.

Shut the breaker off that supplies electricity to the pump control box and check the switch for obvious signs of electrical damage.

If the switch can be pushed up and down easily, and the spring pushes the switch back into an open position, it’s time to move to the well pump control box.

Troubleshooting Pump Control Box

If the pump will not run, the first step is to check the power panel and the specific breaker that supplies electricity to the pump. If there is power to the control box the next step is to check the leads on the pump capacitor.

Bad Well Pump Capacitor Symptoms

A capacitor is a device that supplies a burst of power to an electric motor to get it started spinning.

If a capacity is weakened it won’t supply enough power to start a motor, or it will start the motor sluggishly, making it rev up to speed. This draws a lot of power to the pump motor and can damage or destroy it eventually.

Check the capacitor clips connecting it to the control box. They can come loose over time. If they are, reattach them carefully without making contact with the leads. Capacitors pack a lot of stored energy.

If the leads are intact but the capacitor is hot, doesn’t start the motor, or is damaged in any way, it’s time to get a new pump control box. You can connect the leads to the pressure switch and the pump yourself, or you may wish to call in a professional.

- Manufacturer: Franklin

- Country of manufacture: United States

- Mechanical Components

Well Pump Problems FAQ’s

How Many Years Will a Well Pump Last?

Well pumps last a long time if you regularly check the power control box, the pressure tank, and the pressure switch. Well pumps can provide good service for decades.

How Often Should you Replace your Well Pump?

Ideally, you should never have to replace your well pump. Pumps cost a lot, and removing one from even a shallow well requires expertise, special equipment, and careful rewiring and plumbing of the entire system inside the well casing.

This is one device you should use until it fails, then replace it.

Do well Pumps Need Maintenance?

No well pumps do not need maintenance, but the pressure switch, pressure tank, and power control box will need to be checked, and sometimes replaced.

A little well pump troubleshooting now and then can add many years to the life of your pump.

A power control box can last for decades, just as a pump does. A pressure tank has a lower lifespan, sometimes lasting up to 20 years, and sometimes requiring replacement every 8 to 12 years. The lifetime of your pressure tank is determined primarily by your water quality.

Hard water, with dissolved solids, is hard on a pressure tank, while soft water can let a pressure tank work smoothly for decades.

Thank you for explaining that if the pump is still running but isn’t producing a lot of water, then the impellers inside the pump have worn down. My daughter was saying that there’s really low pressure at her new home and I know that she has her water hooked up to a well. I wonder if this could be her issue, but I’ll pass it on to her just in case so that she can start checking it out and see if someone can come and help her get it fixed soon.

Glad you found the info helpful.

I found it interesting when you said that implementing a simple solution could help prevent major pump problems. My friend informed me a couple of days ago that they were planning for a new well pump installed on their farm for an updated pump system. He asked if I had thoughts on the best option to consider. I appreciate this instructive article, I’ll tell him it will be much better if they consult a trusted well pump service as they can help with the proper installation.

Have a new pump, new pressure tank, new switch. We are getting water from the pump as it is rated for. We are not seeing pressure building on the new pressure Guage. We are puzzled. What could be wrong?

First, double-check that the gauge itself isn’t faulty; sometimes new gauges can be defective. Make sure all the new components are installed correctly and that all valves are in the right position. Trapped air in the system or even a minor leak in the connecting pipes could also be the culprits, preventing pressure from building up.

Hi Andrew and thank you for taking the time to write up this guide, we have found it very informative.

We currently have a problem with out well pump in that it is making these hammering nosies, Upon close inspection we found the pressure switch to be short cycling and found a faucet to be running but after we shut off the faucet and the pressure switch stopped but the noise later continued. My colleague seems to think its a fault in the pressure containment system causing the well pump to engage and disengage (hammering noise)/short cycling. I am trying to assess the cost of this repair–will you be willing to share what you would do in this scenario?

thank you in advance.

In my experience dealing with well pump issues, the first thing you’ll want to do is identify what exactly is going wrong. I’d start by looking at the pressure switch—see if it’s short-cycling. Trust me, a faulty switch can wreak havoc on your whole system. Then check your pressure tank; it could be waterlogged or maybe it’s lost its air charge. Don’t forget to listen to your pump motor and look over the piping for any signs of leaks or other issues. Once you have a good handle on what the problem might be, you can start considering the costs involved.

Now, let’s talk money. Based on what I’ve seen, a new pressure switch will set you back around $20-$50, not counting labor. If it turns out that your pressure tank needs replacing, you’re looking at anywhere from $200 to $1,000, and that’s just for the tank itself. Pump motor issues? Those can be a real wallet-drainer, with costs ranging from $300 to $1,200 depending on the type of pump. Labor usually goes for $50-$100 an hour, so keep that in mind. And don’t forget, you might also have to replace some pipes, connectors, or control units, so add a bit more to your budget for those incidentals.